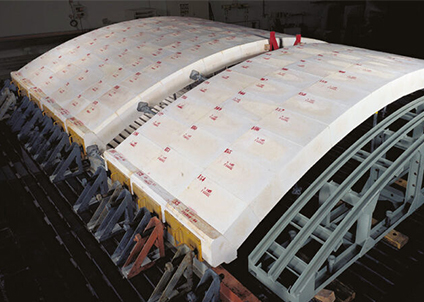

Low thermal conductivity, more energy saving

The constituent substances include nano-active materials with a micro-pore structure, which endows the product with excellent heat insulation performance. Materials of the same thickness can make the outer wall temperature of the kiln lower and more energy-efficient.

No shrinkage and minor gaps after heating

Within the specified operating temperature range, the permanent linear change rate is ≤-0.5%, and it does not continuously shrink even after long-term use. However, for the ordinary thermal insulation boards, the permanent linear change rate reaches -2% ~ -3%, and the shrinkage amount is more than four times. The insulation layer composed of all-inorganic insulation layers, when operating for a long time at high temperatures, shrinkage gaps is small resulting in better protection for the structure.

All-inorganic material, completely free of fibers and organic matter, can be used for a long time under various working conditions without powdering or decaying.

High strength and wide application range

It has a relatively good cold crushing strength. Compared with ordinary insulation boards, its cold crushing strength can reach more than three times of ordinary ones, and it also has excellent strength after burning. It is more reliable and has a wider range of applications when used for a long time at high temperatures.

E.It is non-irritating to the human body, pollution-free to the environment, healthy and environmentally friendly

The product is composed of all inorganic materials and contains no components that irritate human skin. It can be naturally degraded in the environment, making construction and maintenance more convenient, healthier for the human body and more environmentally friendly to the environment.

F.Good quality control, large production capacity, not restricted by environmental protection, and delivery time guaranteed.

It is produced by a fully automatic continuous production line, featuring large production capacity, high production efficiency and good quality control. The delivery period is short, which can meet the delivery period requirements of various large-scale projects. Moreover, throughout the entire production process, there are no polluting links at all, and it is not subject to environmental protection restrictions, making the delivery time more guaranteed.