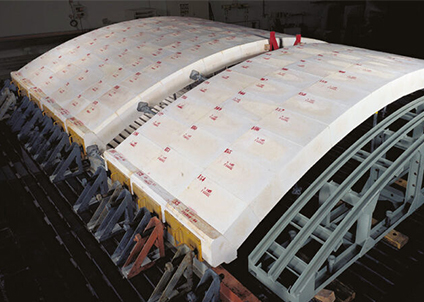

G950 type nano insulation board is a high-performance material developed and manufactured by our company with the latest high-tech technology. Its thermal conductivity is lower than that of still air. At high temperatures, its heat insulation performance is four times of traditional fibrous and microporous calcium silicate insulation materials. It is the better heat insulation performance up to now.

G1000B type nano insulation board is a high-performance material independently developed by our company by applying the new nano composite technology and relying entirely on our own research and development. It has excellent insulation performance. Its heat insulation effect is twice of that for the traditional fiber products and microporous calcium silicate products. At the same time, it has better temperature resistance and durability, and is unlikely to experience crystallization and powdering, and its insulation effect does not decay, with excellent application performance. Nano insulation boards are widely used in various thermal kilns and equipment, which can meet the higher standards of design and usage choices for engineering and technical personnel in this field. Better insulation effect significantly reduces heat loss, driving the realization of energy conservation and consumption reduction goals in various industries. In areas where space is strictly restricted, the application thickness is thinner.

| Item | Unit | YD-G950 | YD-G1000B | |

| BD | g/cm3 | 0.26 | 0.5 | |

| -0.02~+0.04 | ||||

| CCS | MPa | ≥0.3 (Compressed 10%) | ≥0.7 (Compressed 10%) | |

| Thermal conductivity at 350oC | w/(m·K) | ≤0.025 | ≤0.04 | |

| Linear shrinkage rate | % | -1.5~+0.5 (900℃×12h) | -1.5~+0.5 (950℃×12h) | |

| Service

temperature |

℃ | ≤950 | ≤1000 | |

| Chemical

composition |

SiO2 | % | 80 | 85 |

| SiC | 12 | – | ||

| Others | 10 | 15 | ||